A well made, surge protected plug strip is highly recommended for the accessories, upgrades, and peripherals. The “outlets” provided to power the water pump and exhaust fan are not suitable for use. The quality control for the wiring harnesses in these units is about as varied as the rest of the machine so great care needs to be taken to go through the wiring and make sure there are no bad terminations, loose lugs & screws, grounding issues, etc… These machines can be hazardous as far as the AC power and the high voltage power supply ( flyback) goes. YOU CAN FIND A DIAGRAM OF OUR SETUP AT THE BOTTOM OF THIS ARTICLE. Okay, now that that’s all taken care of we can dig into the necessary initial modifications for a K40 to greatly enhance its performance and reliability. There are many options and we cover a cost-effective solution in this article.

#Laserdrw power install#

Let me say that a different way: You MUST install Air Assist. They are poorly designed and poorly wired. Do not plug anything into the “electrical outlets” on the machine. Take the included exhaust fan and ductwork out of the machine and very carefully place it into the nearest trash receptacle. The tube of “goo” (silicone sealant) is for insulating the high voltage connections on the laser tube and nothing else. If you don’t like to tinker, if you are not at all mechanically inclined, or if this is a mission-critical business appliance you may want to find a US laser.Ĥ. If that sounds fun to you then you will love it!ģ. These lasers vary greatly in build quality and require a good deal of “tinkering” to keep them going. Try to provide accurate descriptors and/or photos when referencing your machine.Ģ.

Please, for the love of all that is holy, never refer to your K40 as the “blue and white one” or the “orange and white one”. Please make note of these observations and suggestions:ġ. Let’s get a few items out of the way from the beginning. An American made, precision, workhorse that was built in 1991.

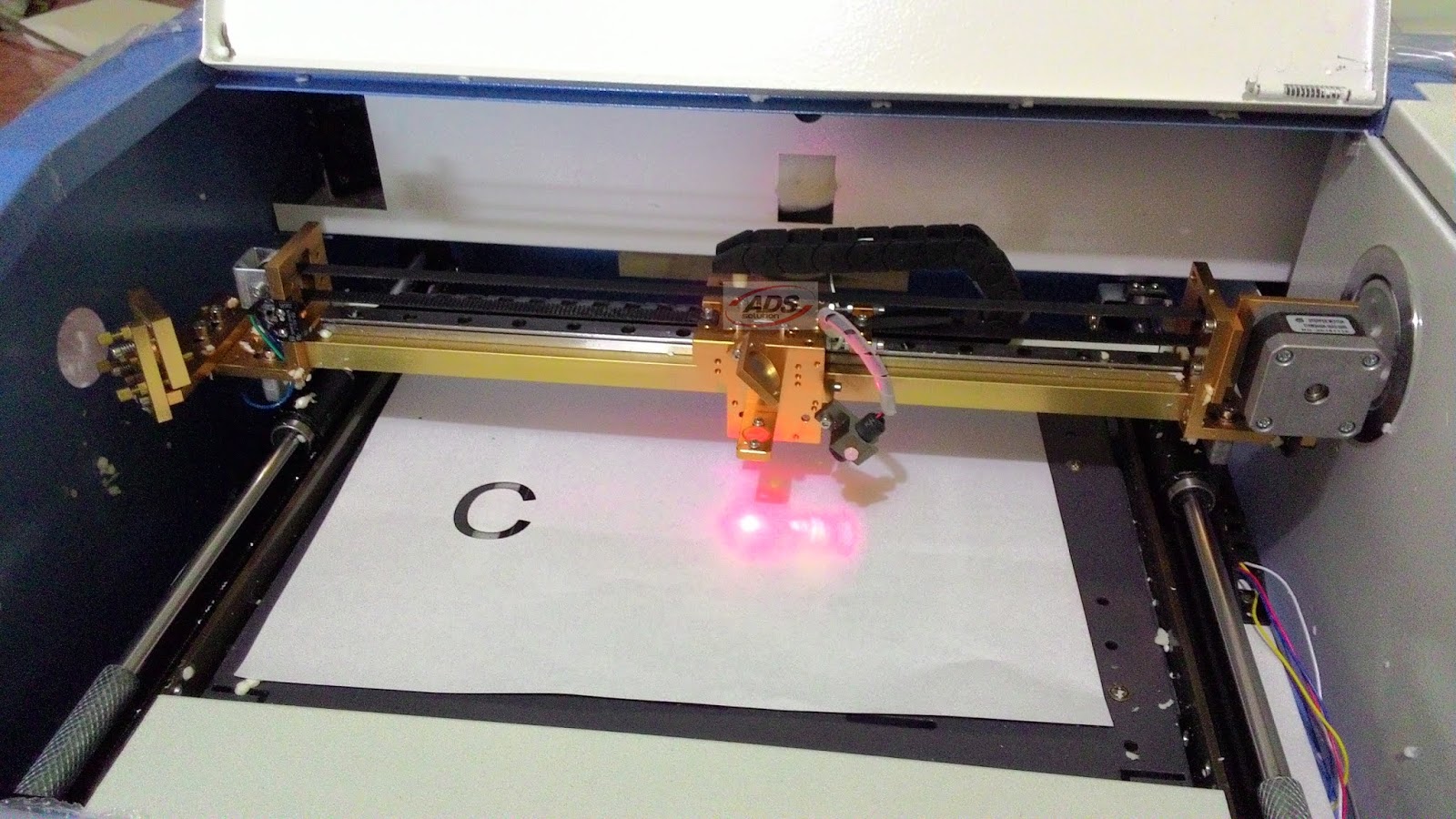

The reason I reference this unit in that manner is that my first experience with a laser engraver was spent on my ULS-25E. We have done hundreds of hours of research on every aspect of these units and, with great input from many great people, have navigated through the initial rough waters of getting a poorly made Chinese clone of a machine to run far beyond our expectations. The laser is very good at making solid dark lines and marks, but I'd like to space out the pinpoints that it makes further apart so that there are less firings per line and less lines overall in the image, speeding up the process but also lowering the accuracy.If you are considering buying, or have just purchased a K40 Chinese Laser Engraver this Knowledgebase Article is the perfect place for you to start (well, except for maybe the safety article). Is there a way to space the firing of the laser to a lower resolution? I don't mean resizing the image itself. Right now it is at the lowest it can be and it still burns fairly dark marks into the wood I'm using. Is there a way to adjust the amount of power the laser uses for the image with the software? I'm aware of the dial on the machine.

#Laserdrw power software#

Is there any way to use a vector file with this software so that the laser, instead of sweeping back and forth horizontally, follows the path laid out by the image? (for example: drawing the square instead of working its way down doing one dot at a time on each of the left and right sides of the square)

#Laserdrw power manual#

Is there a software manual anywhere for either LaserDRW or Coreldraw?

#Laserdrw power series#

I have gotten it to work, but I am here because I have a series of problems that I haven't been able to fix with it. (feel free to ask any questions about them here, as there do not seem to be any good google results for either) Hello, I recently purchased this engraving laser and it came with the notoriously bad Chinese LaserDRW3 software alongside CorelLaser which have both been difficult to get used to.

0 kommentar(er)

0 kommentar(er)